Heat Soaked Thermally Tempered Glass

Description

Reviews

First Glass, a leading China Heat Soaked Thermally Tempered Glass Supplier, delivers premium-quality glass for architectural and industrial applications. Holding Australian CSI certification (AS 2208:2023) and CE certification (EN 12150-2:2004), we are among the few in China meeting these prestigious standards. With advanced technology and strict quality control, we provide safe, durable, and customized glass solutions.

Heat Soaked Thermally Tempered Glass

Heat Soaked Thermally Tempered Glass (HST) is a type of heat soaked tempered glass, which is soda-lime silica tempered glass (HST) that has been subjected to specific process conditions.

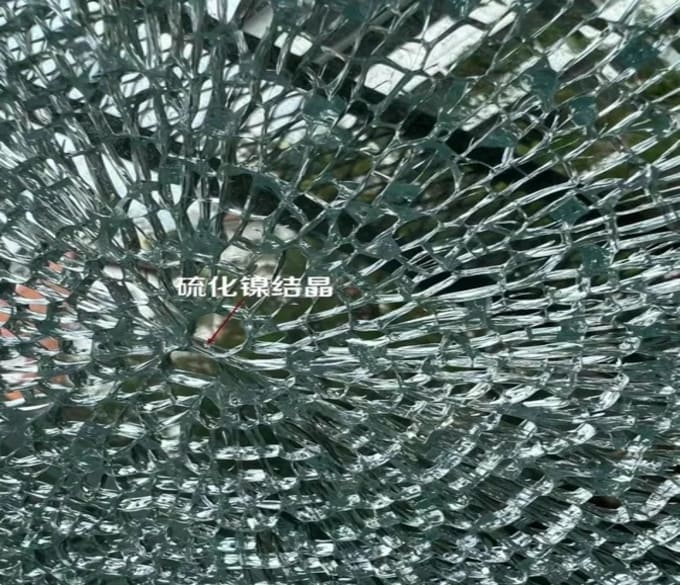

Reasons for tempered glass explosion

Toughened glass explosion is due to the glass manufacturing process mixed with sulphur and nickel impurities, at high temperatures to generate nickel sulphide. Nickel sulfide has two kinds of crystallisation, high temperature (t>380 ℃) is the α phase, low temperature is the β phase. During tempering, due to rapid cooling, the α-phase can not be converted into the β-phase in time. In the process of use, the room temperature of the stable α-phase slowly transformed into a stable β-phase, accompanied by about 4% of the volume expansion caused by the tempered glass explosion.

Benefits of tempered glass after homogenising treatment

The role of the homogenising furnace is to make the nickel sulphide α-phase completely transformed into a low-temperature stable β-phase, out of the glass are not possible to spontaneous detonation (detonation), can effectively ensure that consumers use the tempered glass of the shower room without spontaneous detonation possible. Deng Yu Sanitary Ware is the world's first manufacturer to launch the homogeneous glass shower enclosure, has begun production of homogeneous tempered glass shower enclosure.